CONTACT US

Add: No.25, Longpu Road, Dongcheng Development Zone, Huangyan District, Taizhou City, Zhejiang, China

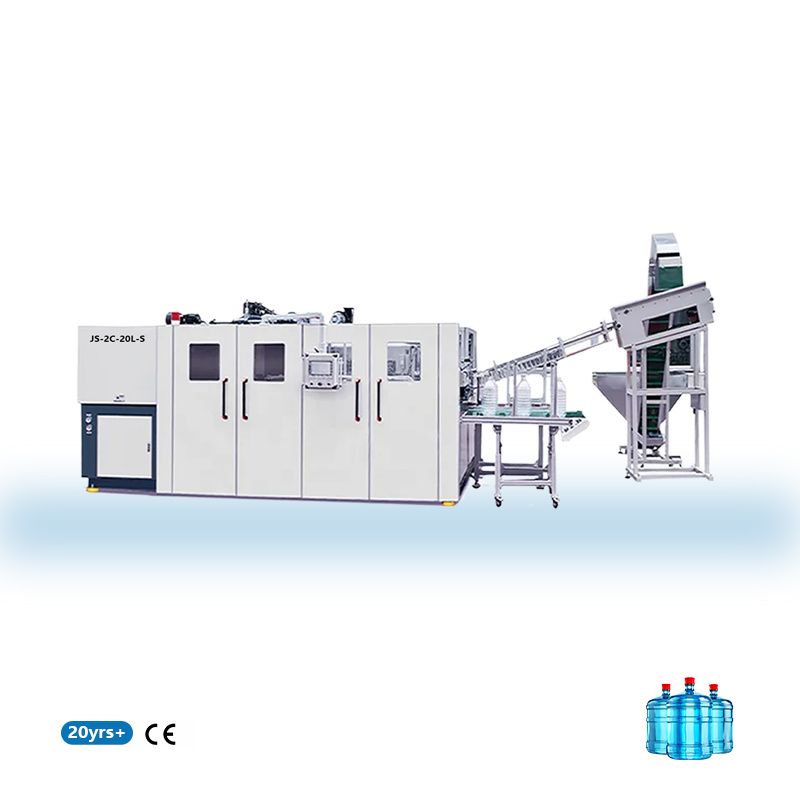

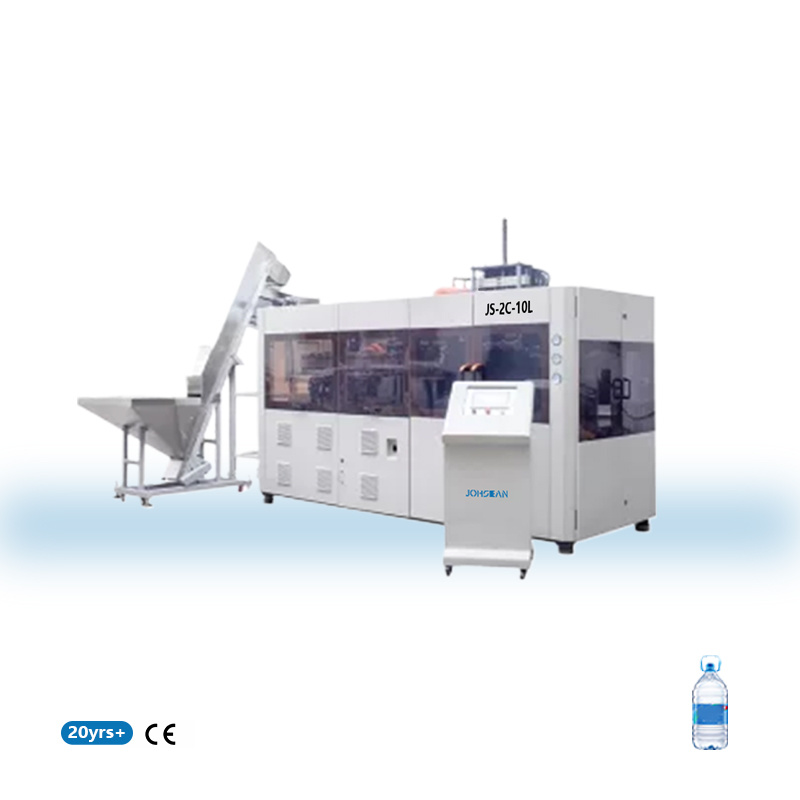

Factory Direct Sale 2 Cavity 20L PET Top Linear Automatic Plastic Bottle Making Machine

Technical Parameters

| Project | UNIT | JS-2C-10L-S |

| Number of cavities | PC | 2 |

| Maximum capacity of bottles | L | 20 |

| Maximum outer diameter of the bottle finish | mm | 100 |

| Maximum outer diameter of the bottle | mm | 290 |

| Maximum height of the bottle | mm | 480 |

| Theoretical yield | B.P.H | 1800 |

| Heating power | KW | |

| Total power | KW | |

| Voltage/frequency | V/HZ | |

| Operating pressure | Bar | 8 |

| Low pressure air consumption | L/min | 1500 |

| Blowing pressure | Bar | 35 |

| High pressure air consumption | L/min | 16000 |

| Dimensions of the machine | M | 5*2.5*2.3 |

| The weight of the machine | KG | 7500 |

Product Introduction:

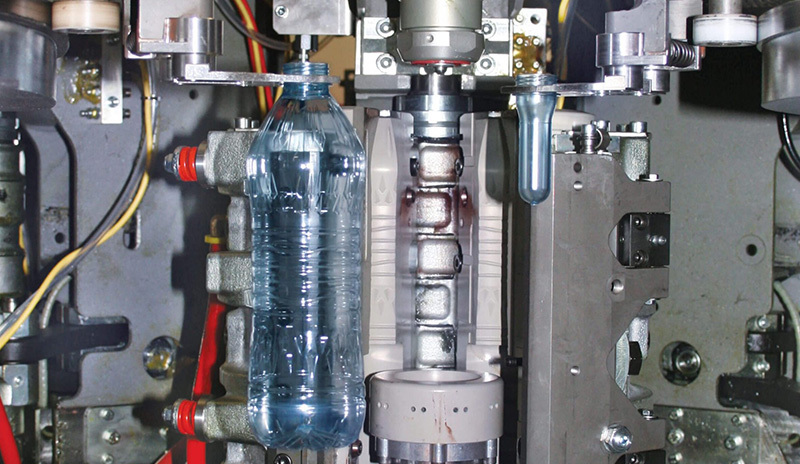

When it comes to producing large-capacity PET bottles with precision and speed, this quality plastic pet bottle making machine made in China stands out as a top choice. Engineered for industrial-scale efficiency, the Factory Direct Sale 2 Cavity 20L PET Top Linear Automatic Plastic Bottle Making Machine features dual-cavity synchronization, significantly boosting output compared to single-cavity models. Whether you need uniform 20L bottles for water, chemicals, or other liquids, this machine ensures flawless molding with its upward-blowing design, eliminating defects like flying edges or eccentricity.

What makes this customized plastic PET bottle making machine from China truly exceptional is its adaptability. Designed to handle varying production demands, it allows adjustments for different bottle sizes and specifications without compromising efficiency. With a theoretical yield of up to 1800 bottles per hour, it maximizes productivity while maintaining consistent quality. The machine’s robust construction and energy-efficient operation further enhance its appeal, making it a cost-effective investment for businesses aiming to scale up production. If you’re seeking a quality plastic pet bottle making machine made in China that combines reliability, speed, and customization, this model is an outstanding solution tailored to modern manufacturing needs.

From seamless automation to precision engineering, this machine exemplifies innovation in PET bottle production. Its user-friendly interface ensures smooth operation, reducing downtime and maintenance hassles. Whether you’re a seasoned manufacturer or expanding your production line, this customized plastic PET bottle making machine from China offers the perfect blend of performance and versatility, setting a new benchmark in the industry.

Product Advantages

Build over two decades of experience in PET blow molding, Johsean's blow molding solutions are dedicated to delivering excellence in quality, safety, adaptability, competitiveness, and ecological advantages. Our team of experts specializes in tailoring solutions to match your product and production requirements at every stage.

Johsean offering personalized machine designs with options for reduced carbon footprint. Our pioneering, robust, and patented solutions are designed to optimize production efficiency through customized blowing processes to suit your specific demands.

Explore the evolution of our blow molding technology and discover how it can elevate your future PET machine production!

Features

Fully Automated Operation

Energy-saving technology are frequently used into full automatic machines to reduce power usage during operation.

High Production Capacity

Fully automatic blow molding machines are perfect for high-volume production because they can crank out a lot of bottles per minute.

Flexibility

They provide manufacturers versatility because they may be set up to create bottles in a variety of sizes, shapes, and patterns.

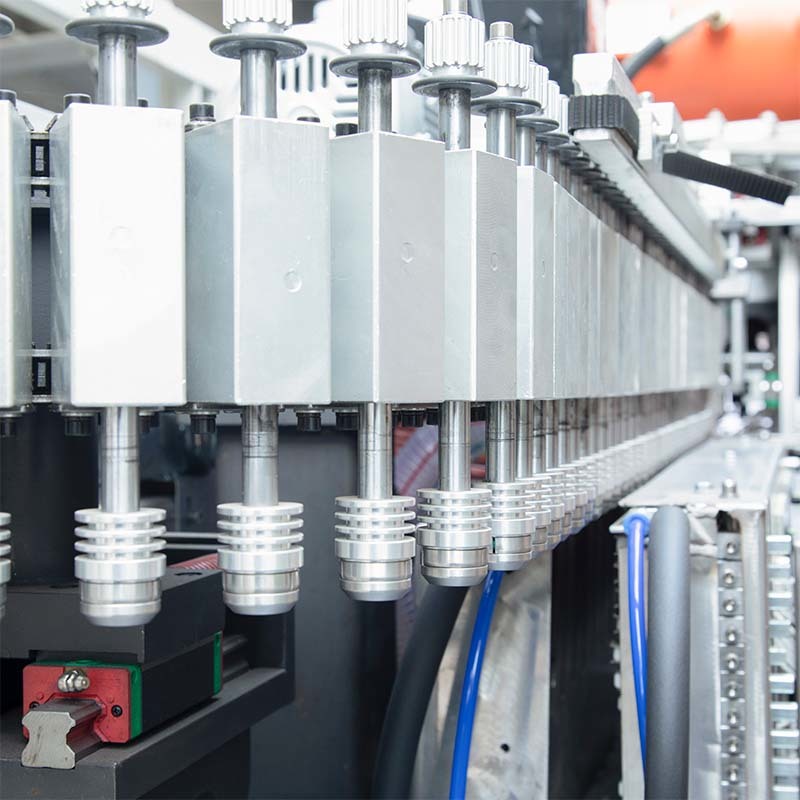

Efficient Heating and Cooling Systems

For accurate temperature control during the blow molding process, these machines are outfitted with cutting-edge heating and cooling systems.

User-Friendly Interface

Many models come with user-friendly interfaces that make it simple to change settings, track production, and identify problems.

Energy-Efficient Design

Energy-saving technology are frequently used into full automatic machines to reduce power usage during operation.

Benefits

High Productivity: Full automatic blow molding machines have a remarkable capacity for production, which boosts overall output and shortens production times.

Consistency: Automation guarantees uniform bottle shapes, constant product quality, and fewer manufacturing flaws.

Labor Savings: These machines require little manual assistance, which lowers labor costs and eliminates the need for skilled operators, making them efficient.

Waste reduction: Exact control over the blow molding procedure lowers material waste and raises manufacturing efficiency as a whole.

Customization for Various Industries: Due to their adaptability, these machines are employed in a variety of industries, including the food and beverage, cosmetics, pharmaceutical, and more.

Energy Efficiency: Many models include energy-efficient elements that cut down on power usage and support sustainability programs.

Product Video

Product Inquiry

Get in touch with our team promptly and we'll be happy to assistyou help