CONTACT US

Add: No.25, Longpu Road, Dongcheng Development Zone, Huangyan District, Taizhou City, Zhejiang, China

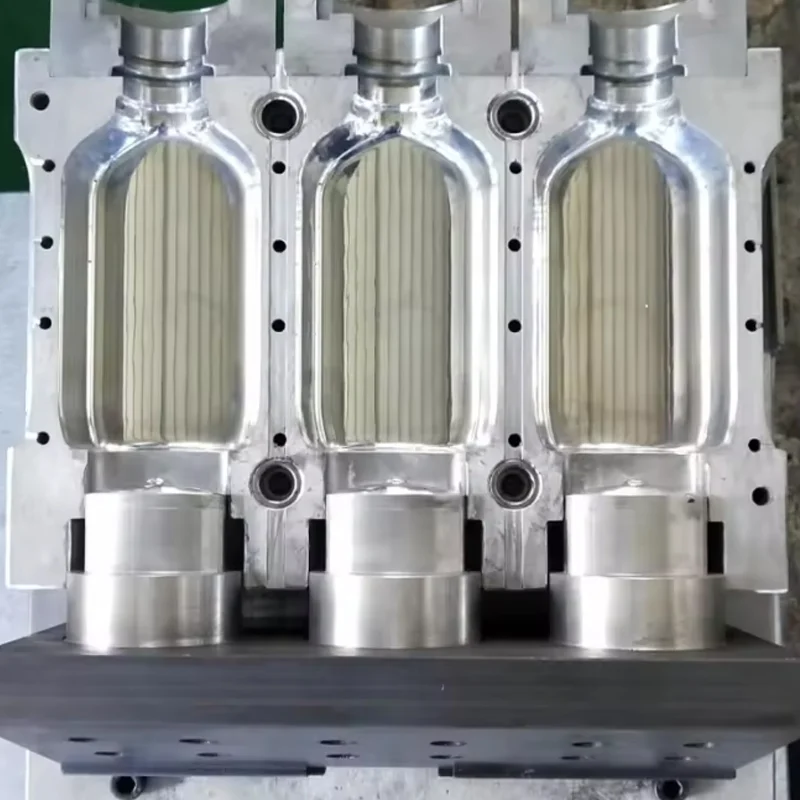

3 cavity 250ml bottle molds

Technical Parameters

| Shaping Mode | pet stretching blowing mould |

| Place of Origin | Zhejiang, China |

| Brand Name | JS |

| Model Number | 500ml-20L |

| Product Material | 45# steel ,stainless steel,7075 |

| Product | water juice cooking oil bottles soap bottles |

| Product Name | plastic bottle mold |

| Mould material | 45# steel,45# steel ,stainless steel,7075,2316 |

| Packaging Details | WOODEN PACKING |

| Selling Units | Single item |

| Single package size | 200X350X180 cm |

| Single gross weight | 67.000 kg |

Lead time

| Quantity (sets) | 1 - 1 | 2 - 2 | 3 - 3 | > 3 |

| Lead time (days) | 15 | 20 | 25 | To be negotiated |

We are now introducing the high-quality 3 cavity 250ml bottle molds. These molds are precisely designed to create bottles with a capacity of 250ml and feature three cavities for efficient production. They are made of durable materials, ensuring long-term use and reliable performance. Whether for industrial manufacturing or small-scale production, these 3 cavity 250ml bottle molds offer excellent shaping capabilities and can meet the diverse needs of various industries.

Product Advantages

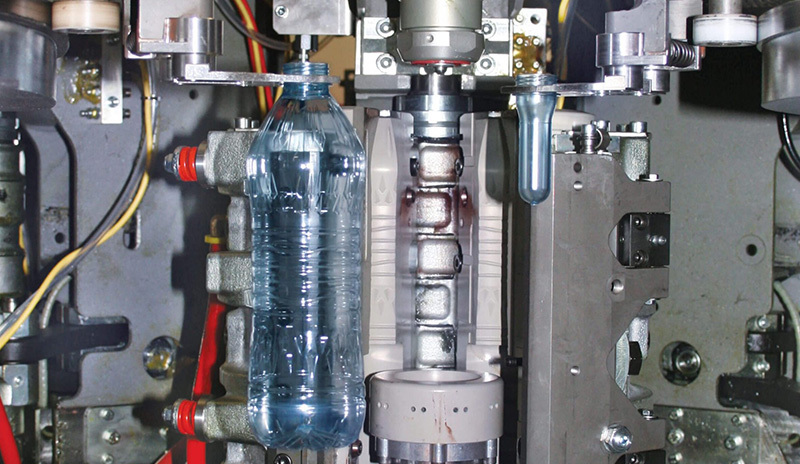

Build over two decades of experience in PET blow molding, Johsean's blow molding solutions are dedicated to delivering excellence in quality, safety, adaptability, competitiveness, and ecological advantages. Our team of experts specializes in tailoring solutions to match your product and production requirements at every stage.

Johsean offering personalized machine designs with options for reduced carbon footprint. Our pioneering, robust, and patented solutions are designed to optimize production efficiency through customized blowing processes to suit your specific demands.

Explore the evolution of our blow molding technology and discover how it can elevate your future PET machine production!

Features

Fully Automated Operation

Energy-saving technology are frequently used into full automatic machines to reduce power usage during operation.

High Production Capacity

Fully automatic blow molding machines are perfect for high-volume production because they can crank out a lot of bottles per minute.

Flexibility

They provide manufacturers versatility because they may be set up to create bottles in a variety of sizes, shapes, and patterns.

Efficient Heating and Cooling Systems

For accurate temperature control during the blow molding process, these machines are outfitted with cutting-edge heating and cooling systems.

User-Friendly Interface

Many models come with user-friendly interfaces that make it simple to change settings, track production, and identify problems.

Energy-Efficient Design

Energy-saving technology are frequently used into full automatic machines to reduce power usage during operation.

Benefits

High Productivity: Full automatic blow molding machines have a remarkable capacity for production, which boosts overall output and shortens production times.

Consistency: Automation guarantees uniform bottle shapes, constant product quality, and fewer manufacturing flaws.

Labor Savings: These machines require little manual assistance, which lowers labor costs and eliminates the need for skilled operators, making them efficient.

Waste reduction: Exact control over the blow molding procedure lowers material waste and raises manufacturing efficiency as a whole.

Customization for Various Industries: Due to their adaptability, these machines are employed in a variety of industries, including the food and beverage, cosmetics, pharmaceutical, and more.

Energy Efficiency: Many models include energy-efficient elements that cut down on power usage and support sustainability programs.

Product Video

Product Inquiry

Get in touch with our team promptly and we'll be happy to assistyou help