CONTACT US

Add: No.25, Longpu Road, Dongcheng Development Zone, Huangyan District, Taizhou City, Zhejiang, China

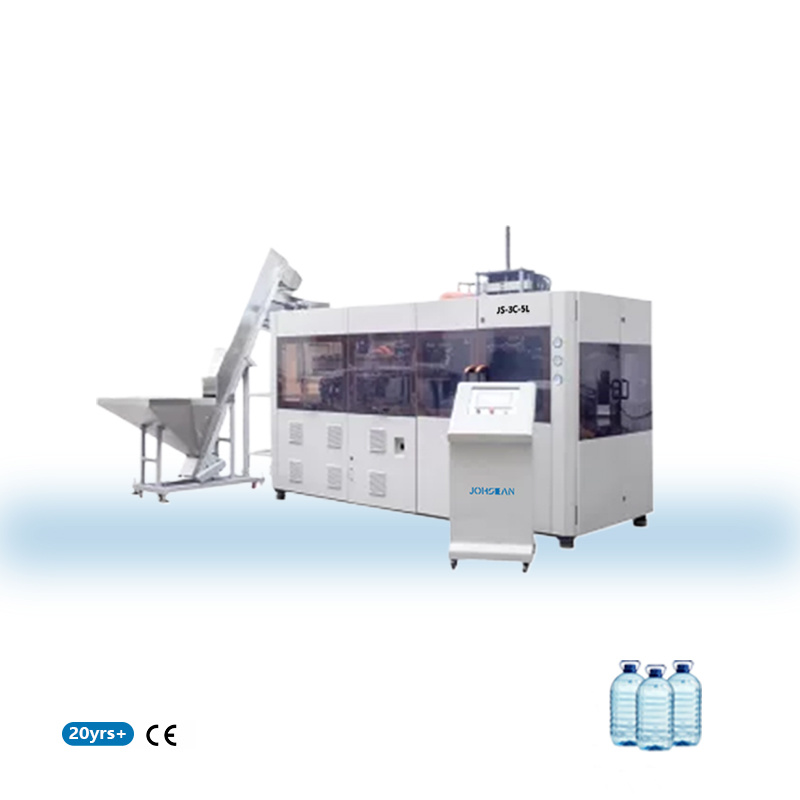

5L cheap price PET Semiautomatic Stretch Bottle Blow Molding Machine for Jar Bottle

Technical Parameters

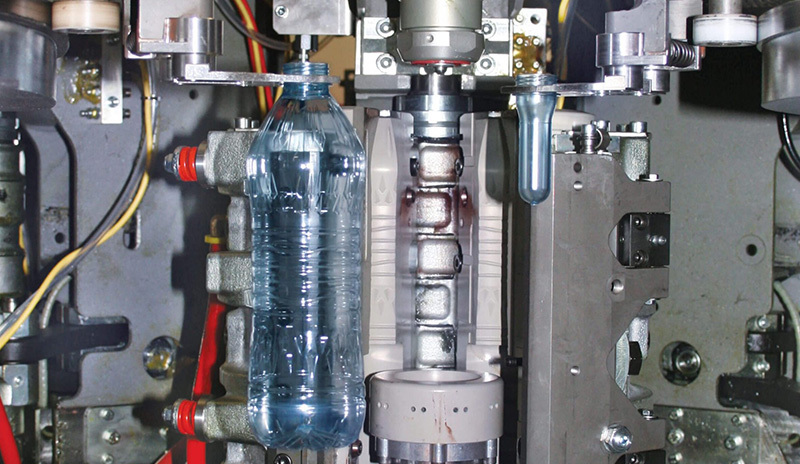

Featuring a compact and sturdy construction, this machine is built to withstand heavy-duty use while occupying minimal floor space. Its semi-automatic functionality allows for easy operation, reducing labor costs and minimizing human error. The machine's precise temperature control system ensures uniform heating and cooling cycles, resulting in high-quality finished products with consistent wall thickness and dimensions.

Equipped with an intuitive touchscreen interface, the Semi-Automatic Blowing Machine offers seamless operation and monitoring. Users can easily program and adjust various parameters, including blowing pressure, cycle time, and mold temperature, to achieve optimal production settings. Additionally, its quick changeover capability enables fast mold swapping, enhancing productivity and versatility.

Safety is paramount, and this machine incorporates multiple safety features, including emergency stop buttons, protective barriers, and alarm systems, ensuring operator safety and compliance with industrial standards. Furthermore, its energy-efficient design reduces power consumption, contributing to lower operational costs and environmental sustainability.

| Project | UNIT | JS-5II |

| Production capacity | BPH | 350 |

| Number of Cavity | 1 | |

| Clamping force | KN | 80 |

| Mould opening stroke | mm | 230 |

| Stretch stroke | mm | 350 |

| Max. Container Volume | L | 5 |

| Max. Neck Size | mm | 120 |

| Max. Bottle diameter | mm | 180 |

| Max. Bottle height | mm | 350 |

| Installed Power | Kw | 17 |

| Max. Heating Power | Kw | 16 |

| Operating Air Pressure | Kg/cm2 | 8 |

| Operating Air Consumption | liters/min | 200 |

| Blowing Air Pressure | KG/cm2 | 30 |

| Blowing Air Consumption | liters/min | 700 |

| Cooling water Pressure | Kg/cm2 | 4-5 |

| Cooling water Temperature | °C | 10-20 |

| Cooling water Flow | liters/min | 100 |

| Measurement (L x W x H) | M | 2.0*0.65*1 .8 |

| Machine Weight | Tons | 0.65 |

| Infrared Dimension | M | 1.7*0.6*1.5 |

| Infrared Weight | Tons | 0.3 |

Product Advantages

Build over two decades of experience in PET blow molding, Johsean's blow molding solutions are dedicated to delivering excellence in quality, safety, adaptability, competitiveness, and ecological advantages. Our team of experts specializes in tailoring solutions to match your product and production requirements at every stage.

Johsean offering personalized machine designs with options for reduced carbon footprint. Our pioneering, robust, and patented solutions are designed to optimize production efficiency through customized blowing processes to suit your specific demands.

Explore the evolution of our blow molding technology and discover how it can elevate your future PET machine production!

Features

Fully Automated Operation

Energy-saving technology are frequently used into full automatic machines to reduce power usage during operation.

High Production Capacity

Fully automatic blow molding machines are perfect for high-volume production because they can crank out a lot of bottles per minute.

Flexibility

They provide manufacturers versatility because they may be set up to create bottles in a variety of sizes, shapes, and patterns.

Efficient Heating and Cooling Systems

For accurate temperature control during the blow molding process, these machines are outfitted with cutting-edge heating and cooling systems.

User-Friendly Interface

Many models come with user-friendly interfaces that make it simple to change settings, track production, and identify problems.

Energy-Efficient Design

Energy-saving technology are frequently used into full automatic machines to reduce power usage during operation.

Benefits

High Productivity: Full automatic blow molding machines have a remarkable capacity for production, which boosts overall output and shortens production times.

Consistency: Automation guarantees uniform bottle shapes, constant product quality, and fewer manufacturing flaws.

Labor Savings: These machines require little manual assistance, which lowers labor costs and eliminates the need for skilled operators, making them efficient.

Waste reduction: Exact control over the blow molding procedure lowers material waste and raises manufacturing efficiency as a whole.

Customization for Various Industries: Due to their adaptability, these machines are employed in a variety of industries, including the food and beverage, cosmetics, pharmaceutical, and more.

Energy Efficiency: Many models include energy-efficient elements that cut down on power usage and support sustainability programs.

Product Video

5L cheap price PET Semiautomatic Stretch Bottle Blow Molding Machine for Jar Bottle

Taizhou Johsean Machinery Co., Ltd.

5L cheap price PET Semiautomatic Stretch Bottle Blow Molding Machine for Jar Bottle

Taizhou Johsean Machinery Co., Ltd.

Related Products

Product Inquiry

Get in touch with our team promptly and we'll be happy to assistyou help